Strengthening Immunization Waste Management in Afghanistan with HICLOVER TS50 PLC Incinerators

Addressing UNICEF’s Requirements for Safe Waste Disposal

UNICEF’s recent call for safe healthcare waste treatment under the National Expanded Program for Immunization (NEPI) highlights the urgent need for robust, environmentally sound incineration solutions in Afghanistan. With more than 1,500 health facilities generating sharps, used vials, and discarded safety boxes, the challenge lies not only in disposal but in ensuring compliance with global health and environmental standards.

The program outlines clear technical expectations: dual chamber incinerators, batch loading, primary combustion at ≥850°C, secondary chamber retention time of ≥2 seconds at 1100°C or higher, and units sized to fit facilities in Kandahar, Nangarhar, Herat, Balkh, and Paktya. Each site must safely process around 400 safety boxes and 1,000 vials daily, replacing unsafe practices like open burning or burial.

HICLOVER TS50 PLC: A Proven Match for Afghanistan’s Needs

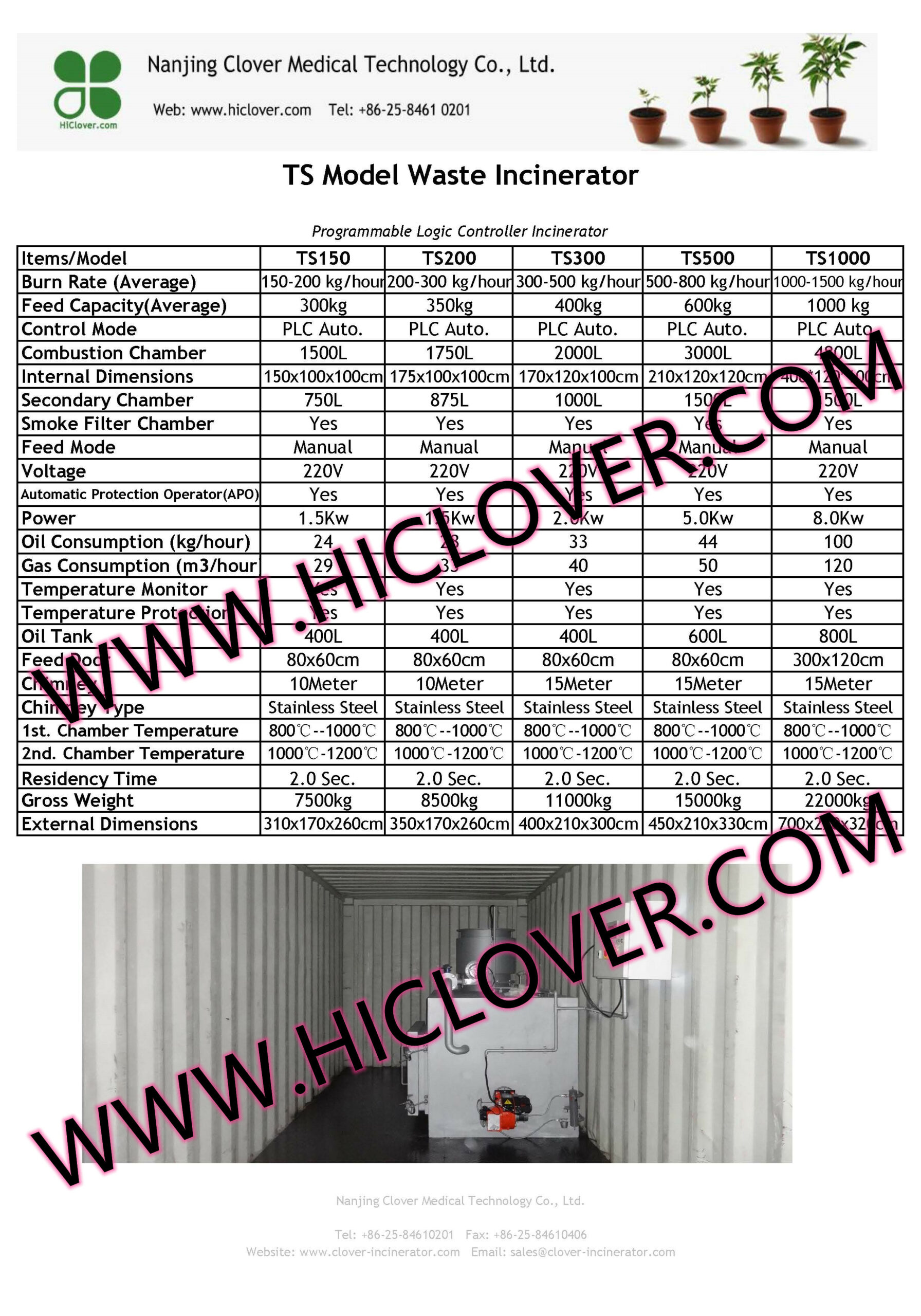

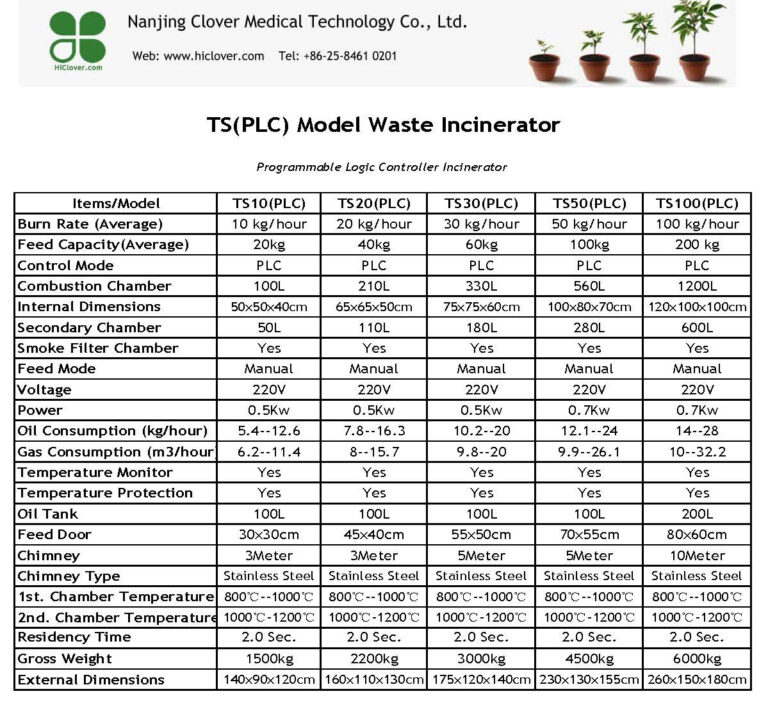

The HICLOVER TS50 PLC incinerator provides the ideal solution. Compact yet powerful, the unit processes up to 50 kg per hour, aligning with UNICEF’s required throughput while fitting within site restrictions of 2.5 × 4 meters.

Key technical highlights include:

-

PLC Automatic Control: Ensures precise temperature regulation and automated safety shutdowns.

-

Dual Chamber Design: Primary chamber for solid waste breakdown; secondary chamber for flue gas treatment, ensuring complete destruction of pathogens and toxins.

-

High-Temperature Retention (HTR): Adjustable retention settings with thermocouples rated up to 1600°C for reliable monitoring.

-

Sealed Doors and Refractory Lining: Prevent gas leaks and withstand continuous high-temperature operation.

This configuration directly responds to UNICEF’s specification for safe treatment of infectious sharps, vials, and pathological residues, while also handling non-combustible waste such as glass ampoules, metal sharps, and containers through deformation.

Enhanced Safety and Reliability

Beyond combustion efficiency, HICLOVER has incorporated advanced safety and sustainability measures:

-

Operators PPE Kit: Each incinerator comes with three full sets of heat-resistant PPE (aprons, gloves, and boots) to protect health workers.

-

Spare Parts Package: A two-year supply of critical wear parts ensures uninterrupted operation in remote Afghan sites.

-

Fuel System Safety: Diesel oil lines are fitted with flame arrestors, automatic shut-off valves, fire-resistant insulation, and a diesel leak detection system to prevent accidents.

-

Noise & Emissions Control: Units operate below 85 dBA, with optional wet scrubbers to minimize acid gases and visible smoke.

Strategic Impact for Afghanistan

Deploying the TS50 PLC incinerators at regional Expanded Program for Immunization hubs will:

-

Provide a standardized, WHO-compliant disposal method for immunization waste.

-

Reduce risks from open burning and uncontrolled dumping.

-

Protect healthcare staff with modern safety equipment and training.

-

Establish a scalable model for other Afghan provinces and neighboring regions facing similar waste management gaps.

SEO Keywords

afghanistan medical waste incinerator tender

HICLOVER TS50 PLC dual chamber incinerator

hospital immunization waste disposal Afghanistan

UNICEF supported healthcare incinerator project

diesel incinerator with flame arrestors and leak detection

two year spare parts incinerator package Afghanistan

Learn More

HICLOVER provides CE-certified, ISO-compliant incinerators designed for healthcare, humanitarian, and oilfield operations worldwide.

-

Website: www.hiclover.com

-

Email: sales@hiclover.com

-

WhatsApp: +86-13813931455